Micro- and nano-electronics device manufacturing integrates a sequence of process steps often based on complex kinetics which must be controlled with high accuracy. New requirements, due to the integration of innovative materials or to the more aggressive specification of the next-coming technological node, make ever and ever inefficient the conventional strategy based on “almost” blind Design of Experiments (DoE) procedures (i.e. large matrix of characterizations analyses varying the process parameters). The use of accurate methods for the Technology Computer Aided Design (TCAD) able to simulate the atomistic evolution of the material during the processes at the experimental time-space scale (i.e. minutes-microns) could represent a critical supporting tool for the development of next device generations.

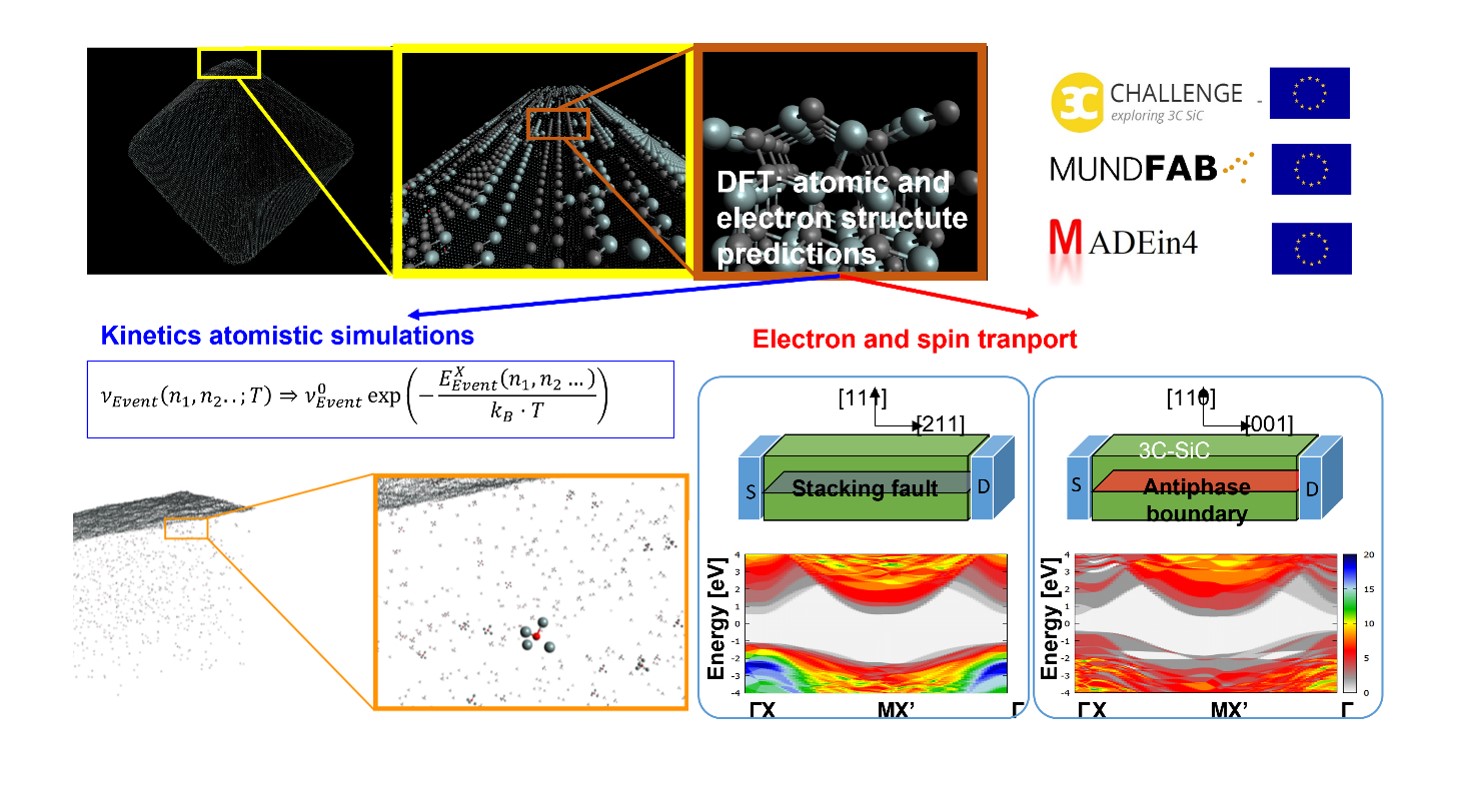

The IMM-Catania is an internationally recognized centre for the computational researches supporting the implementation of innovative TCAD tools, and in this contribution an overview of current state of the IMM TCAD activities will be given. Kinetics of systems at different scale concurs to the processes’ performances; therefore the predictivity of numerical techniques relies on a multiscale approach, where the top level (few hundreds atom and quantum mechanics theory) consists in accurate ab-initio studies. The different methods, the observable quantities which they simulate, their integration from macro to the micro scales, their predictivity potential and the comparisons with reference experimental studies will be presented. Particular focused arguments will be discussed in the details which are argument of recent European projects [1-3]. Finally, a brief presentation of the proprietary open-source project MulSKIPS [4], where IMM advanced codes will be integrate for a fast and universal use, will be given.

[1] CHALLENGE Project www.h2020challenge.eu

[2] Madein4 Project https://madein4.eu

[3] MUNDFAB Project www.mundfab.eu