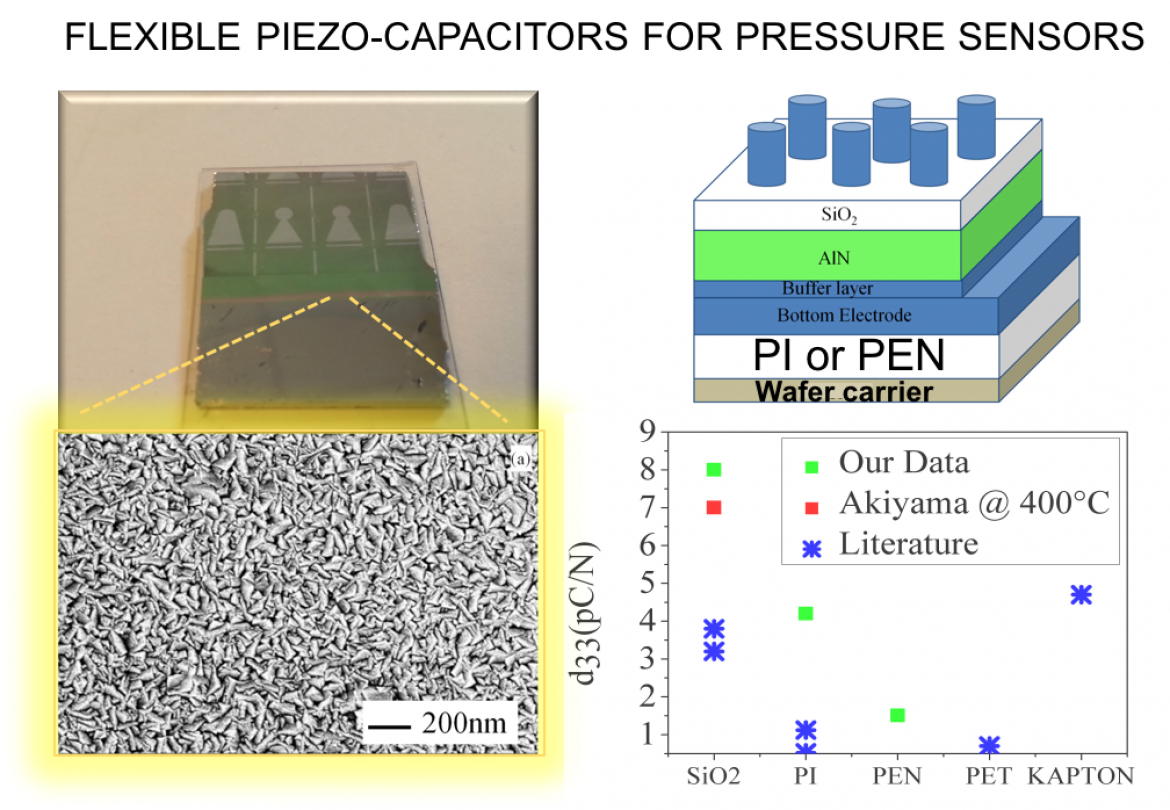

It is well assessed that AlN-based (inorganic) flexible pressure sensors represent a highly competitive alternative to polymers-based piezoelectric devices, since, in spite of their relatively lower piezoelectric coefficients, they offer a number of advantages: inorganic piezo-materials do not need poling processes; they can have excellent linear response to the applied mechanical stimulus; their implementation on large area industrial processes is reliable; they could require low thermal budget even if some crucial aspects are still unexplored or not fully understood. In AlN-based pressure sensors the texturing of the active material along its c-crystallographic axis is mandatory to improve the d33 piezoelectric constant. In our approach we mainly focus on Al/AlN-based devices and explore the manifold role of the interface to trigger the growth of highly c-axis-oriented hexagonal AlN layers using sputtering deposition at low temperatures, with the intent of finding out a reliable strategy to implement piezocapacitors on flexible substrates. We currently propose a strategy which employs a thin Al buffer layer, to be deposited at 160°C immediately before AlN without vacuum interruption, to avoid interfacial contamination and, consequently, to offer the prerequisite for a proper AlN texturing. With this approach, high piezoelectric performances are achieved which are really competitive also on flexible substrates with respect to the actual literature results. Taking care about the material structures and interfacial properties is thus nowadays mandatory and represents our guideline for any further approach in this field.

Contact Person: Alessandra Alberti